COHABITATE

Yale School of Architecture | Spring 2017 | Peter de Bretteville

2017 Jim Vlock Building Project

Project Website: CLICK HERE

2017 Jim Vlock Building Project as seen in the Wall Street Journal - The Best Architecture of 2017: Buildings of Quiet Ambition

Since 1967, first-year students at the Yale School of Architecture have worked collaboratively to design and build a structure as part of their graduate education. In recent years, the Building Project has focused on the design and construction of affordable houses in New Haven's economically distressed neighborhoods.

For the first time, in 2017 the Yale School of Architecture partnered with Columbus House, a non-profit organization that has been providing solutions to homelessness in the New Haven area since 1982.

The design brief targeted a 1,000 square foot house of two separate dwellings, to be located on a lot in New Haven's Upper Hill neighborhood. We were challenged to develop a cost-efficient, flexible design that adressed replicability in material, means, and method of construction.

Through a series of studies, the following proposal sets up not only a modular system to meet the criteria of prefabrication and method of delivery, but also an interactive language in which clients can actively engage and express their individual preferences in the design.

A STUDY OF MODULAR HYBRIDITY

A design exercise to study elements of the New Haven vernacular home in relation to the modular mid-century Metabolist movement in Japan, particularly the work of Kisho Kurokawa. The resulting exploratory model fuses elements of structure, scale, communal organization, and method of construction between the two housing types.

Diagram by Kurokawa illustrating assembly method of concrete structural components for mass apartment complex, creating a series of sites for the placement of interchangeable modular bathroom and kitchen ‘pods’

Model Assembly - A video illustrating the reconfigurable nature of tropes of the New Haven house and neighborhood fused with symbiotic principles of Metabolism

Resulting model configuration

A study of co-habitation

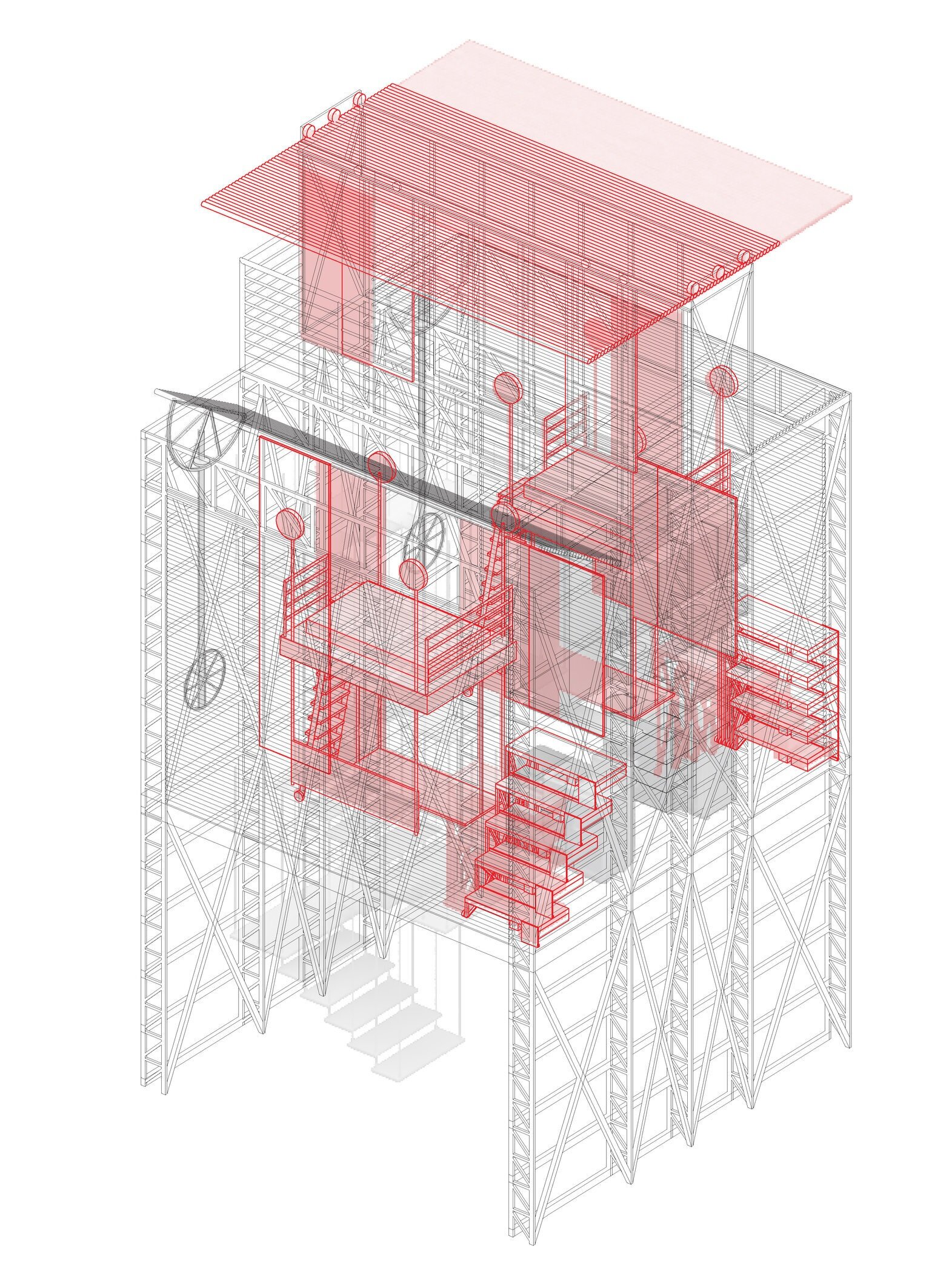

An exercise exploring opportunities for efficiency in the design of a two unit 'co-habitation'. For purposes of the exploration, the design was limited to a 16'x'16'x14' cube, 12' off the ground, in which light could only enter via the roof structure. The following proposal uses a series of kinetic components (shaded in red) to maximize spatial efficiency including a gantry bed, sliding roof structure (to provide adequate shade throughout the day), and retractable stairs, also serving as shelving.

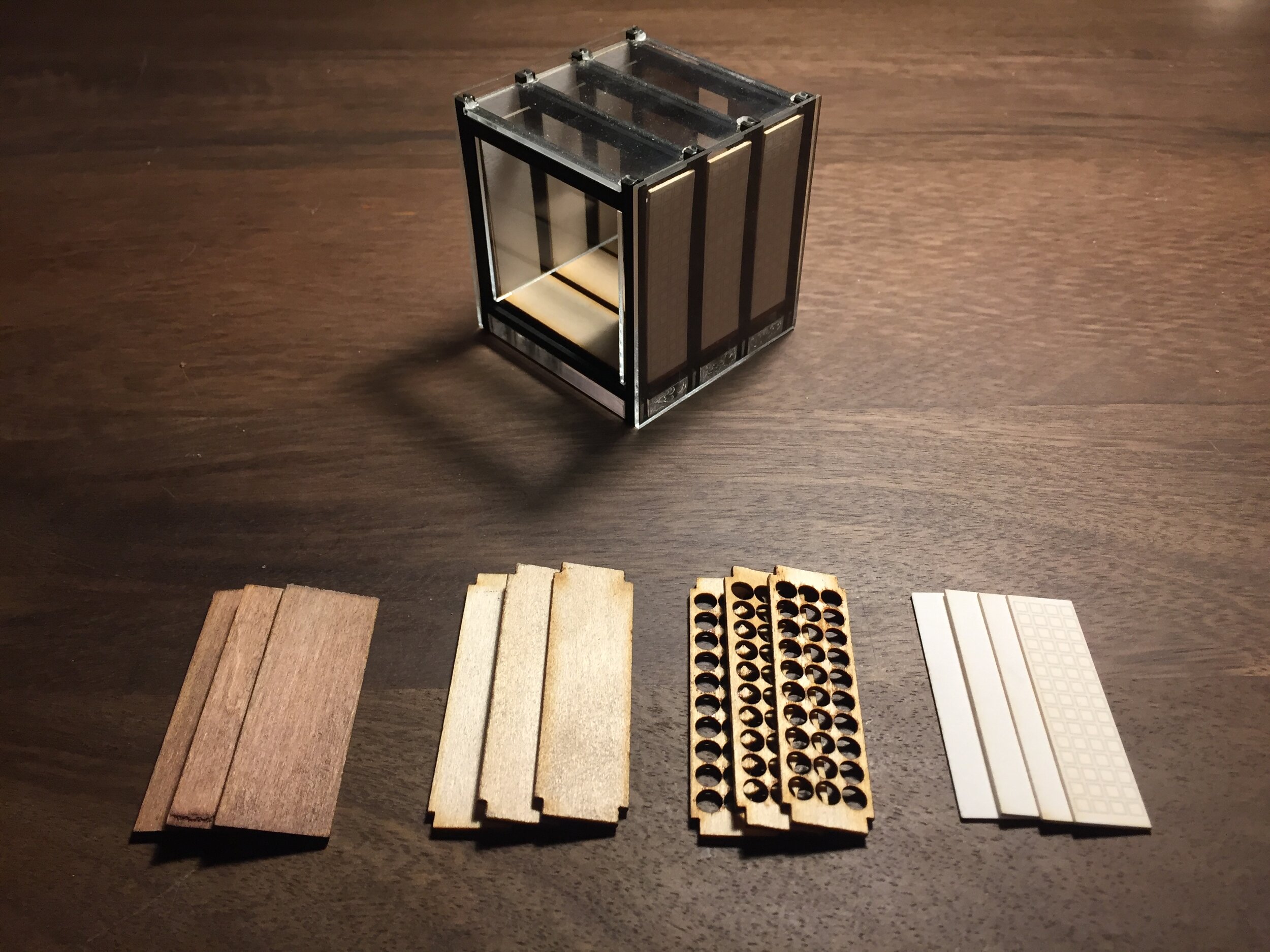

Designing a modular vocabulary

In designing a pre-fabricated residence for formerly homeless clients, one must reinvent the design process to be both inclusive and translational between the client and designer. The following exercise sets up not only a modular system to meet the criteria of prefabrication and method of delivery, but also an interactive language of components in which clients can actively engage and express their individual preferences in the design.

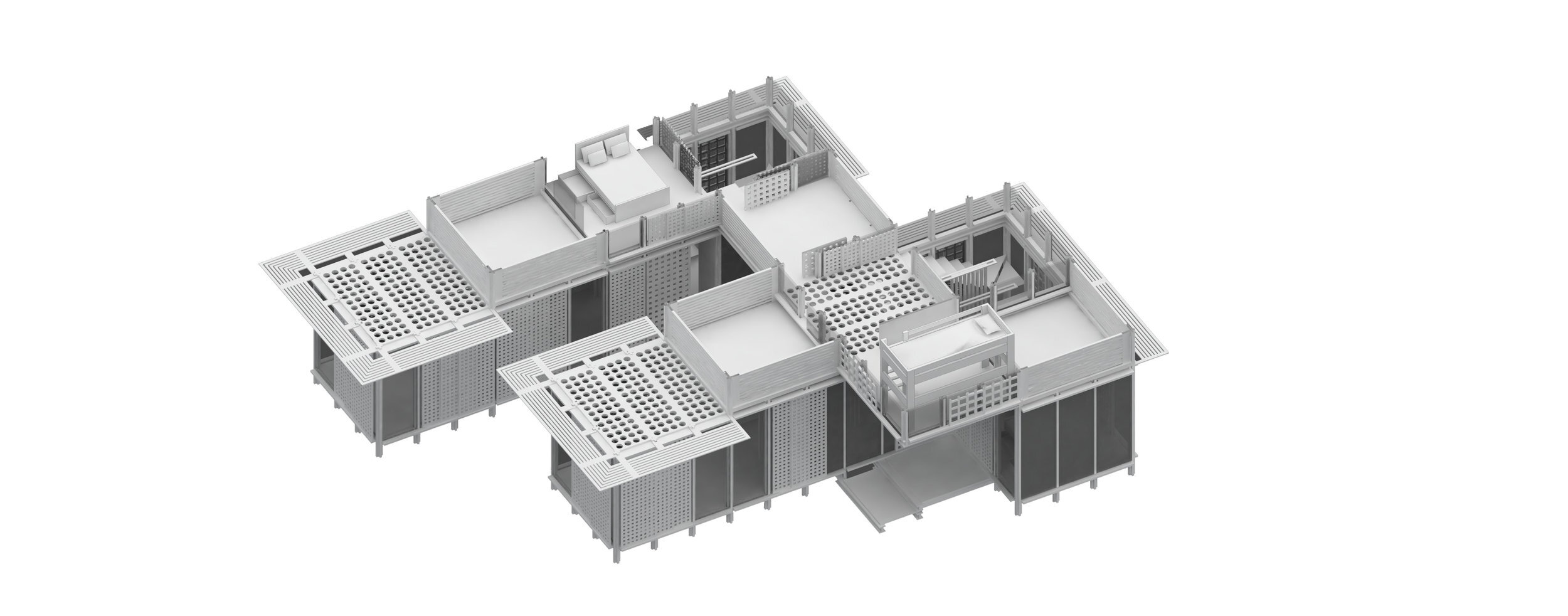

proposal of a Two-Unit Modular prototype

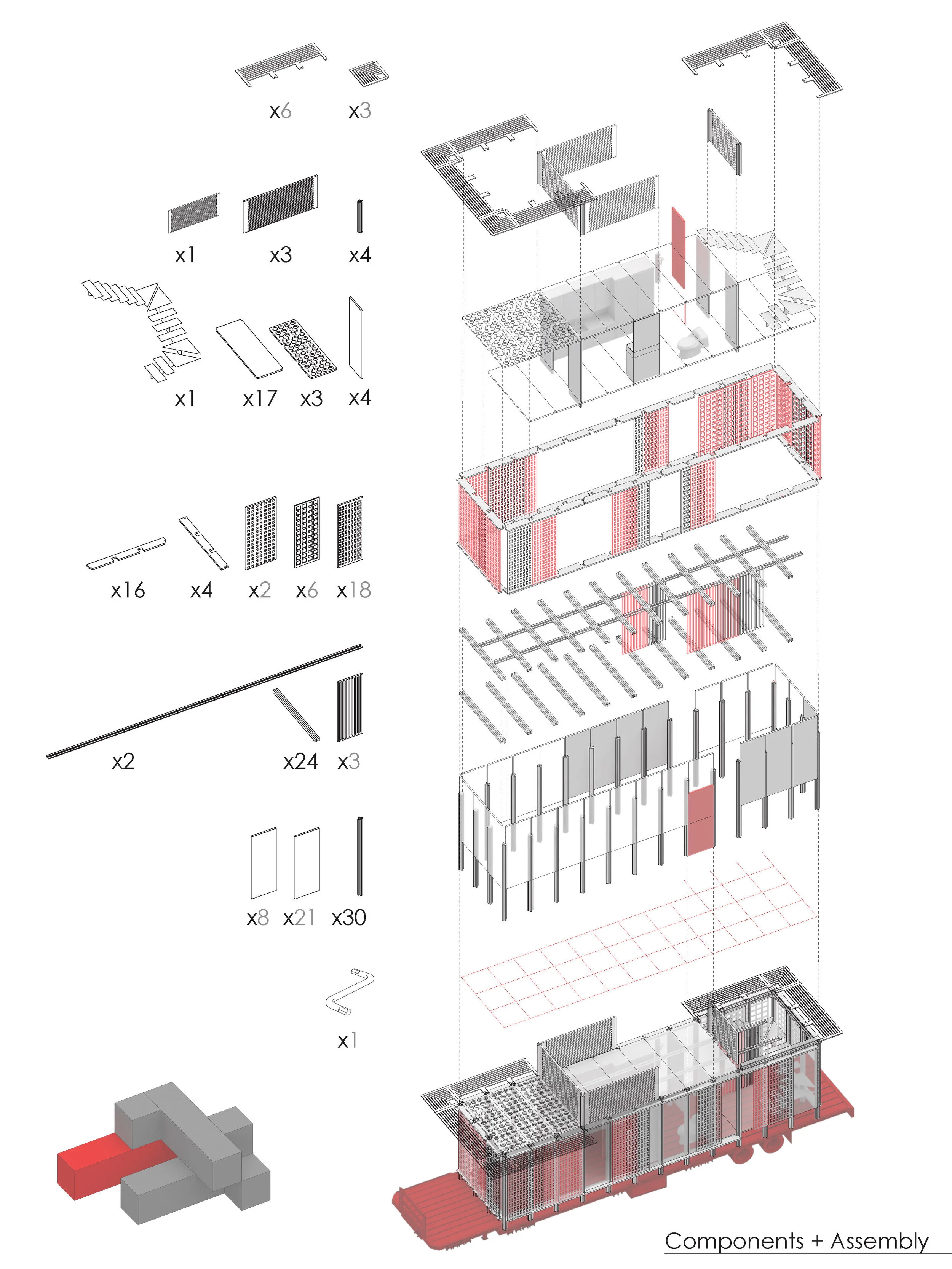

Design and component assembly of a modular two unit apartment to house an individual client and family in separate private units. This proposal studies configurations of modules which can be transported on various types of flatbed trucks to the final construction site.

Study of configurations of modules which can be transported on flatbed trucks to the final construction site

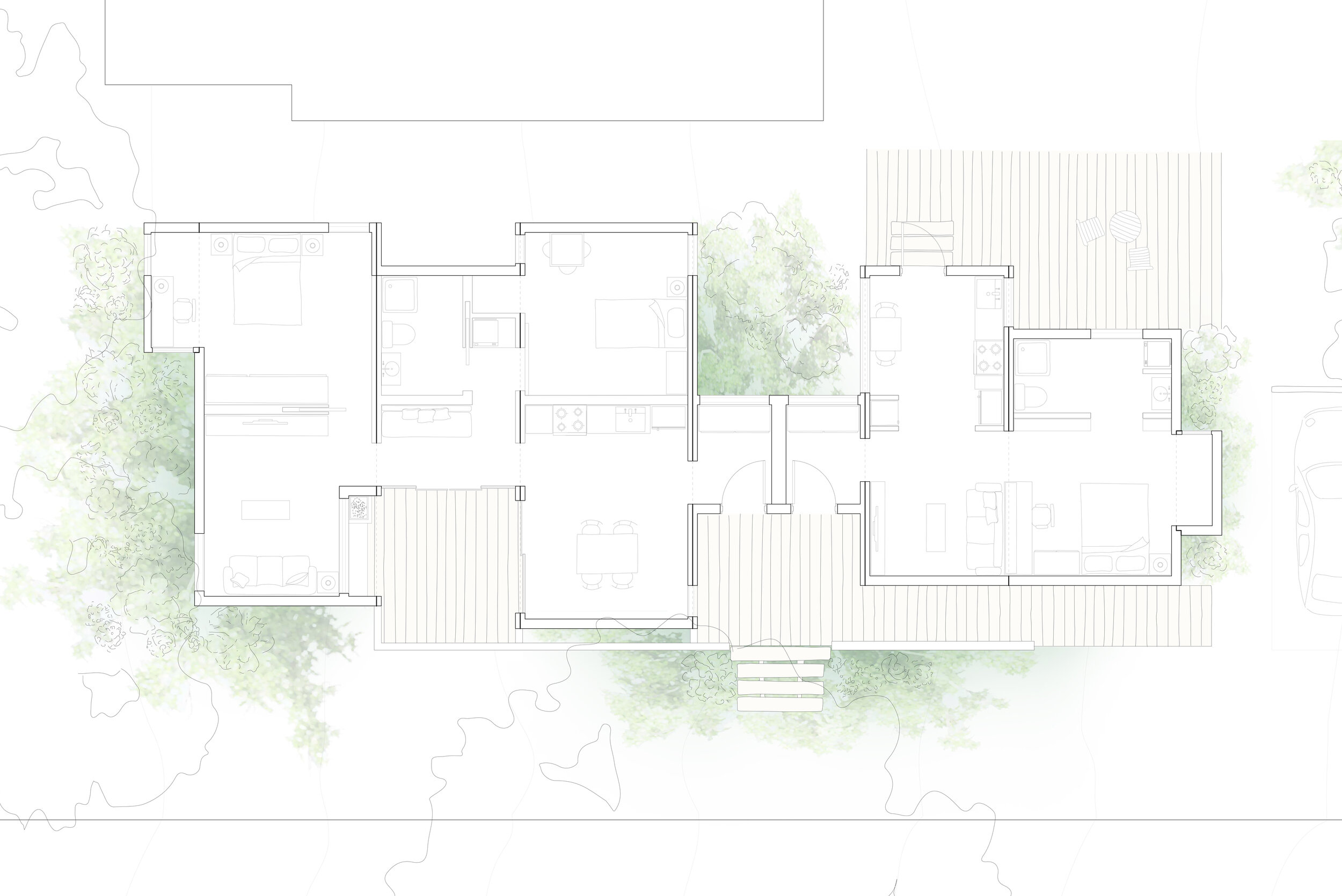

Ground Floor Layout

First Floor Layout

Second Floor Layout

Components and assembly of a single standard module to ship on a flatbed truck

Design and component assembly of a modular two unit apartment to house an individual client and family in separate private units

3/4 scale model of 9'x9' corner of the two unit dwelling, illustrating integration of a stair, bathroom, and operable sliding panel components for desired level of exterior privacy

team proposal

L - R: Pik-Tone Fung, Davis Butner, Gus Steyer, Jeffrey Liu, Samantha Monge Kaser, Gwyneth Bacon-Shone, David Bruce, Martin Man, Kola Ofoman

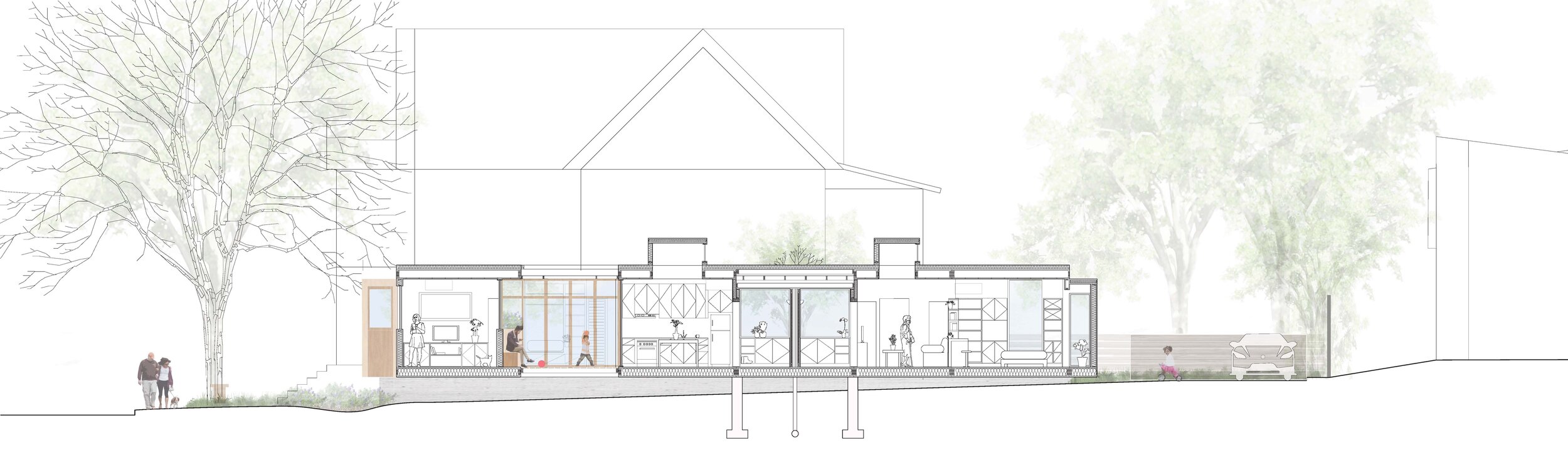

Our proposal explores the spatial and experiential potentials that occur with the slippage of modular volumes. With a strong belief in the efficiency of modular construction, as well as the importance of accessibility, we propose a single-story dwelling comprised of six prefabricated modules which rest on a series of parallel concrete foundation walls. The shifting of these modular spaces creates voids that then function as private exterior courtyards for each unit. Thoughtful placement of the courtyards, as well as the fenestration, allows for a dialogue between interior and exterior, while addressing aspects of safety, security, light, and ventilation. By subsequently elevating each module on thin concrete foundations accessible by a shared entrance ramp, we aim to reduce our footprint to allow for natural drainage along the site’s gradual slope.